EN 9100 ISO 9001

Certifications

HVAC-R

Heating, ventilation and air conditioning systems.

The effectiveness of heating, ventilation and air conditioning (HVAC) systems in today’s buildings, whether residential, industrial or for service activities, is of decisive importance for ensuring the comfort of living and working spaces.

The running of these systems requires various machines for the treatment of the fluids/gases involved in heat transfer: compressors, pumps and fans, all of which are powered by electric motors. These machines are sources of vibration and noise and must therefore be isolated in terms of both airborne and structural transmission in order to safeguard the comfort of the residents/workers.

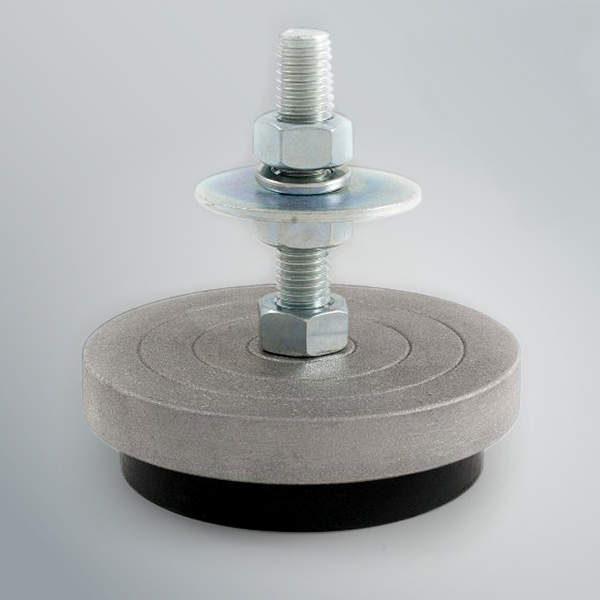

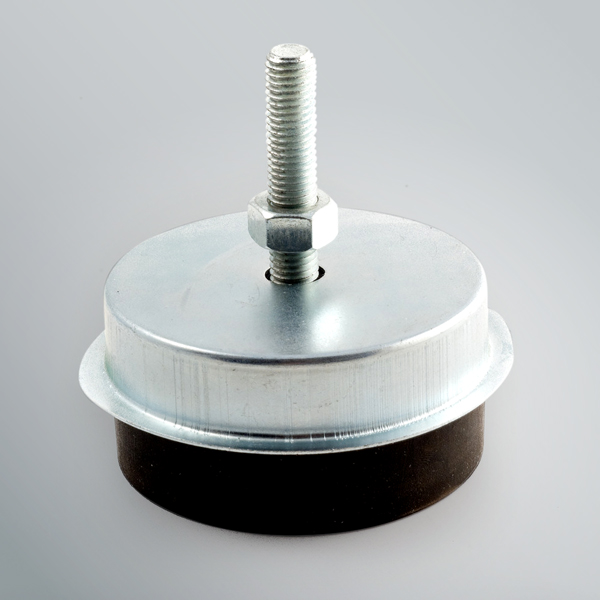

The vibrations generated can be isolated by installing rubber or spring anti-vibration mounts (AA, TSGE, TSPP or MOPLA) between the machine and the support surface.

In other cases it is preferable to place the machine (or groups of machines) on a cement screed, which serves as an inertia base to increase the suspended mass. The concrete screed is separated from the floor slab by a layer of rubber anti-vibration matting (BPD, G).

With installed systems, it is critical to isolate each vibration transmission route, i.e. pipes to and from the machinery must be connected using flexible joints and, if suspended from the ceiling, should be supported with anti-vibration hangers (Mohang, Silentfix or Mopla 1 Hanger), at least for the first few metres downstream from the vibration source.