Vibrostop will exhibit its anti-vibration mounts at the AHR Las Vegas show from 2 February 2026 to 4 February 2026 with SUNNEX INC –

Las Vegas Convention Centre 3150 Paradise Rd Las Vegas, NV 89109 – Booth #SU-2015

Menu

EN 9100 ISO 9001

Certifications

Menu

Mechanical Workings

Home > Applications > Industrial Machinery > Mechanical Workings

Production companies often have continuously running machinery and equipment generating noise and vibrations, which, if beyond certain tolerance thresholds, require isolation in order to protect the health of the workers.

In other cases, machine tools for high-precision machining and test benches for quality control tolerate very low levels of incoming vibration that are incompatible with the surrounding environment.

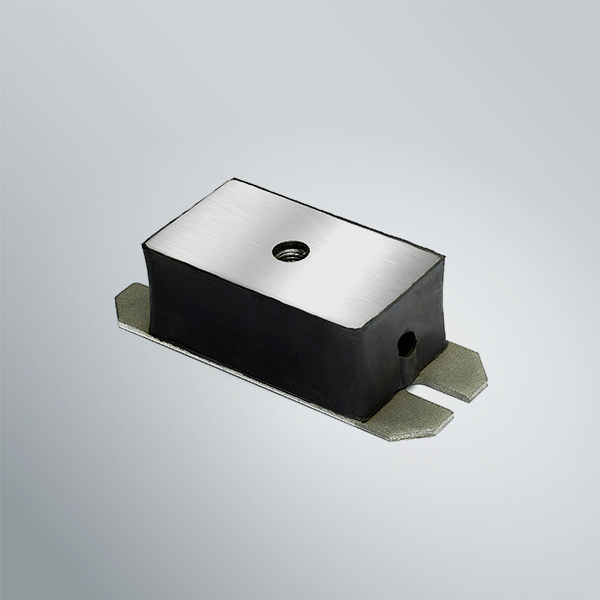

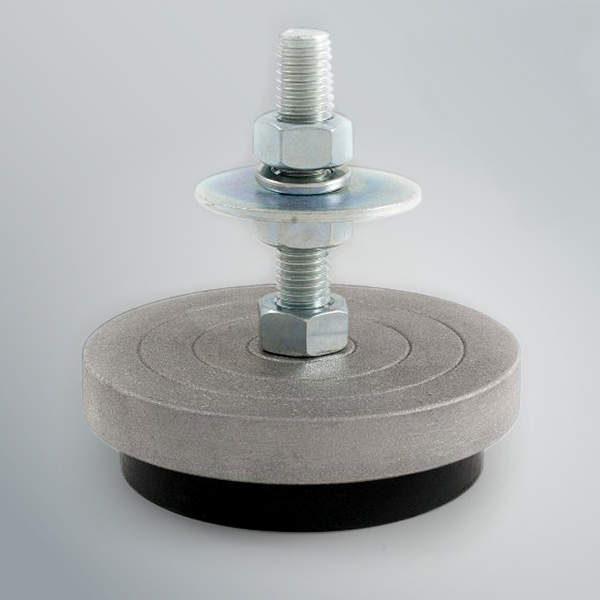

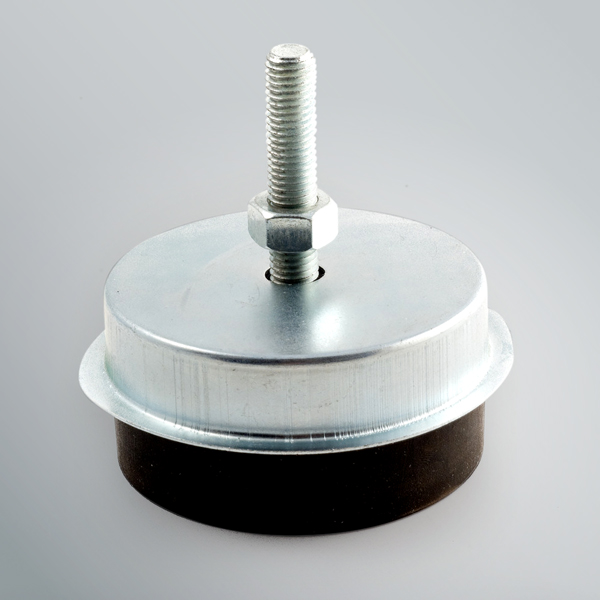

The best solution, which maintains the necessary rigidity of the support surface and increases the suspended mass, is to create a foundation under the isolated machine/equipment resting on anti-vibration mounts (G, BPD, AA and TSZ) to separate it from the surrounding environment.

This solution is impractical in most cases, however, (due to both the cost of the necessary work and production downtime) and so it is preferable to place the machine directly on vibration isolators: either free standing, when friction is sufficient to keep it in place, using the BPD, G, TSGE or TSPP series, or anchored to the floor, if there are significant horizontal forces that can unbalance the machine, using the AA, Flexobloc or TSZ anti-vibration mount series.

HIGHLIGHTS

Anti-vibration mounts for mechanical processing

{"cpt":"service","style":"3","columns":"4","show":8,"from_category":["rubber-antivibration-mounts"],"order":"ASC","orderby":"title"}