We will be closed for holidays from 18/04/2025 to 21/04/2025 inclusive, on 25/04/2025 and from 01/05/2025 to 04/05/2025.

Menu

EN 9100 ISO 9001

Certifications

Menu

Aerospace industry

Home > Applications > Aerospace Industry

Throughout their working lives, electronic parts used in aeroplanes, rockets and satellites are subject to the vibrations present in the structure of the vehicle in which they are installed. The main sources of vibration include the engines, propellers and rotors of aeroplanes and helicopters, and acceleration during the launch of rockets for placing satellites in orbit.

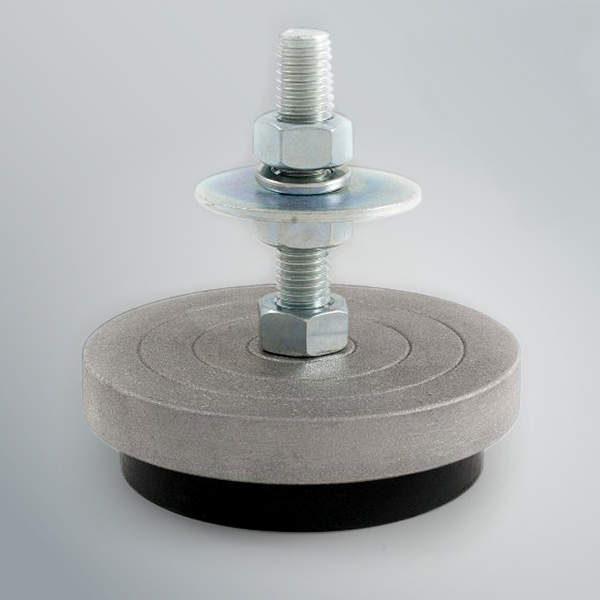

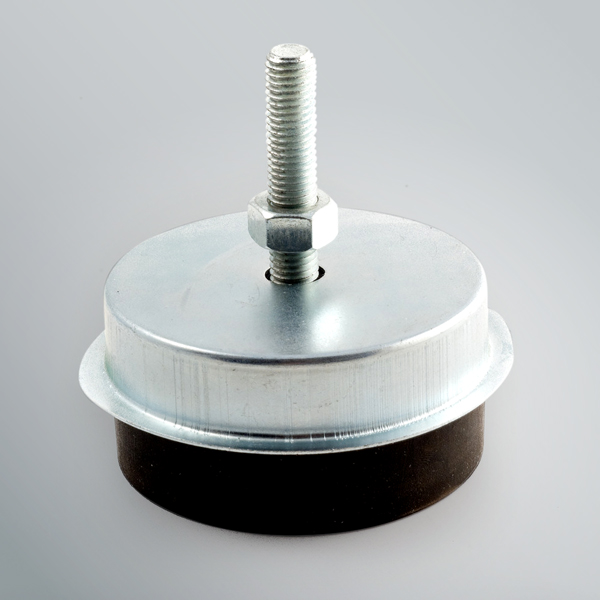

Anti-vibrational mounts are often fitted to enable electronic components to pass compliance tests and then continue functioning properly during their working lives. These supports must not only isolate the equipment, but should do so with extreme reliability over time and be of minimal weight. The smaller models of the AA, AVAU and Cavoflex series have proven suitable for this purpose. The PGM rubber anti-vibration mount is specifically used for isolating cockpit instruments, due to its low profile design that allows it to be submerged in its support structures.

Sensitive aircraft and satellite parts also often need protection from the vibrations and accidental impacts that can occur during transport from the production plant to the final assembly site. For this purpose, transport pallets and containers are made using wire rope isolation technology (Cavoflex) to absorb and dissipate unwanted stress.

HIGHLIGHT

Antivibration for Aerospace

{"cpt":"service","style":"3","columns":"4","show":8,"from_category":["wire-rope-isolators","rubber-antivibration-mounts"],"order":"ASC","orderby":"title"}