Rotating machinery

Home > Applications > Industrial Machinery > Rotating Machinery industry

All rotating machines produce vibrations due to the eccentricity, imbalance and misalignment of rotating parts, due to possible contact and friction between parts and, in some cases, to thermal and fluid-dynamic phenomena inside the machine. All the following types of machines should therefore be considered as sources of vibration: pumps, compressors, fans, electrical motors, internal combustion engines, turbines, reducers, alternators and centrifuges.

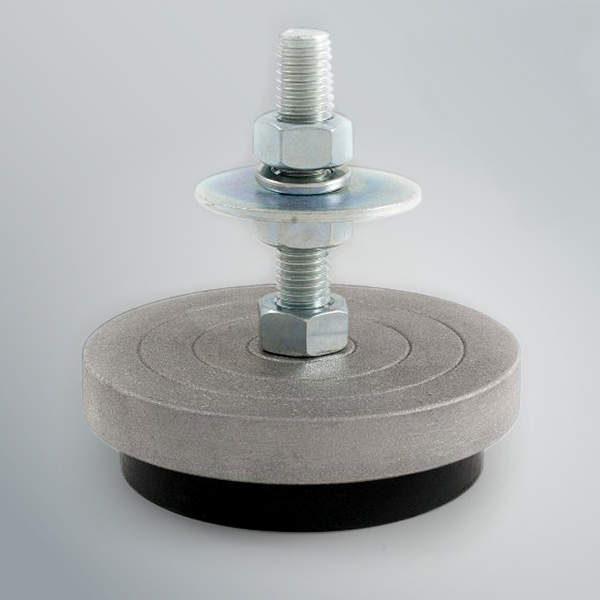

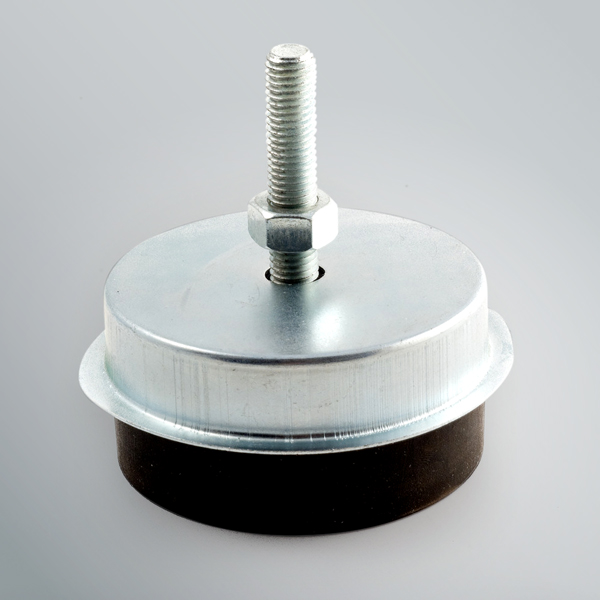

Machines that operate at an almost constant rate, aside from a rapid on/off ramp, and are only subject to moderate horizontal forces, can be isolated using the spring anti-vibration mounts from the Mopla series. The model should be selected in relation to the point load and to attain a suspension frequency of less than a third of the frequency of the principal force (for example, the first order harmonic). This will provide excellent isolation, with up to a 90% reduction of the vibrations that would otherwise be transmitted to the base.

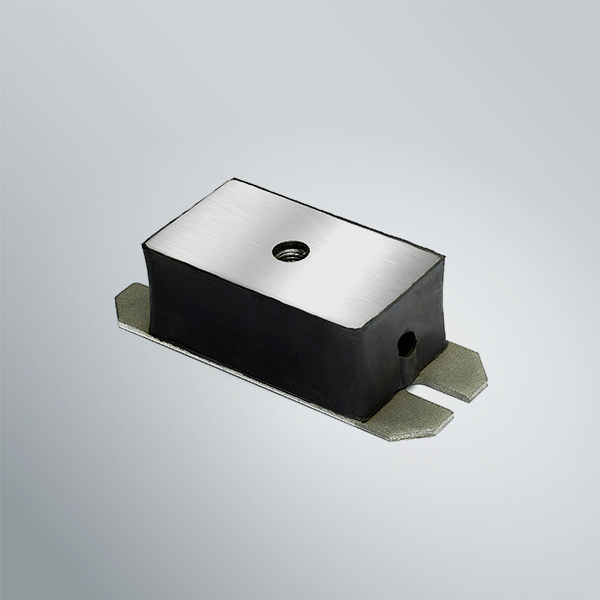

If the machine operates at variable speed, rubber isolators are probably the best choice, since their greater damping properties reduce problems of possible temporary transition from the suspension resonance. Mounts fitted with mechanical safety features, such as AA, TSZ and MM (for aggressive environments or special accidental overload resistance needs) are therefore suitable, or else the simple Flexobloc anti-vibration blocks, in cases without exceptional shear or tensile overloads.

HIGHLIGHTS

Anti-vibration for Rotating Machines

{"cpt":"service","style":"3","columns":"4","show":8,"from_category":["spring-vibration-damper","rubber-antivibration-mounts"],"order":"ASC","orderby":"title"}